Aluminium Paste: Properties, Types, and Modern Applications Explained

2025 / 11 / 19Introduction

Aluminum paste is one of the most widely used metallic pigments today, and is indispensable in coatings, inks, plastics and industrial applications.

Understanding Aluminium Paste

Aluminum paste is made by dispersing finely ground aluminum flakes in a solvent or aqueous medium.

Its value lies in the following three aspects:

-

High metallic brightness

-

Excellent coverage and hiding power

-

Stable performance in both solvent-borne and water-borne systems

At ZHANGQIU METALLIC PIGMENT, our technical team applies over 30 years of manufacturing experience to produce consistent, customizable aluminium paste for industrial use.

Leafing Aluminum Paste

Leafing aluminum paste creates a shiny, mirror-like metallic effect.

This effect occurs because the flakes float to the surface and align horizontally.

Typical uses include:

-

Metal-effect coatings

-

Anti-corrosion and roof coatings

-

Decorative paints and printing inks

It offers strong reflectivity and brilliant silver appearance.

Aluminium Paste Non Leafing

Non-leafing aluminium paste disperses evenly throughout the coating film.

It provides a uniform metallic effect with deeper color and better adhesion.

Common applications:

-

Automotive base coats

-

Industrial machinery coatings

-

Protective paints requiring high bonding strength

This type supports stronger durability and chemical resistance.

Water Based Aluminium Paste

As global industries shift to greener materials, water based aluminium paste is rapidly growing.

It offers:

-

Lower VOC emissions

-

Better environmental compliance (RoHS, REACH)

-

Improved safety in transportation and storage

Our water-based series is designed for eco-friendly coatings, inks, and polymer applications.

Applications, Case Studies & Comparisons

1. Key Application Areas

-

Automotive metallic coatings

-

Plastic coloration

-

Industrial metal-effect finishes

-

Printing inks and reflective paints

-

Anti-corrosion and architectural coatings

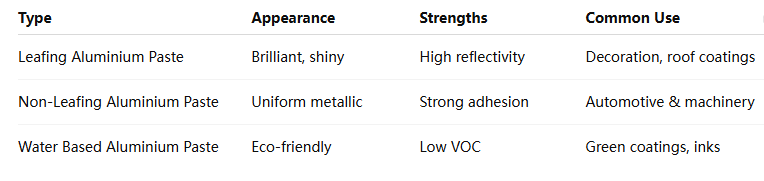

2. Quick Comparison Table

3. Case Study

A European ink manufacturer needed stable, fine-flake aluminium paste for water-borne flexographic printing.

Solution from ZHANGQIU METALLIC PIGMENT: customized water-based aluminium paste with improved dispersion stability.

Result: 15% higher brightness & reduced VOC emissions.

FAQ

1. Is aluminium paste safe to use?

Yes. With proper industrial handling and compliance (e.g., REACH), it is widely used in coatings and plastics.

2. What is the difference between leafing and non-leafing?

Leafing floats to the surface and gives a shiny effect; non-leafing stays inside the film and provides a deeper metallic look.

3. Does water-based aluminium paste perform as well as solvent-based?

Modern formulations achieve similar brightness with lower VOC emissions.

4. Can aluminium paste be customized?

Of course. Particle size, solvent type, gloss level, and coating compatibility can all be customized.

Conclusion & Call to Action

Aluminum paste—whether it is flake aluminum paste, non-flake aluminum paste, or water-based aluminum paste—is a key material in modern coatings and manufacturing.

If you need expert guidance, bulk supply, or customized formulations, ZHANGQIU METALLIC PIGMENT CO., LTD is ready to support you.

Contact Our Technical Team Today

https://zqmetallic.com

info@zqmetallic.com

Let us help you choose the right aluminium paste for your next project.