The Key Role of Aluminum Powder in Silver Paint and Metallic Coatings

2026 / 02 / 06With the continuous development of the industrial coatings and decorative paint industry, silver paint has become increasingly popular due to its outstanding metallic appearance and sparkling effect. It is widely used in construction, machinery, automotive components, and industrial equipment.

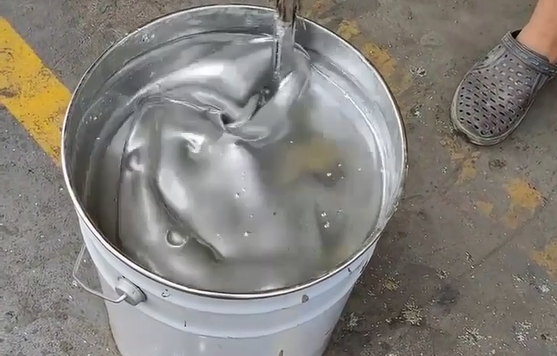

In silver paint formulations, aluminum powder plays a critical role. Its quality and performance directly determine the visual effect, durability, and service life of metallic coatings.

This article provides a comprehensive analysis of the functions, advantages, and application techniques of aluminum powder in silver paint systems.

1. Composition of Silver Paint and Metallic Coatings

Silver paint is a functional coating with a bright metallic appearance. It is mainly composed of the following components:

-

Aluminum powder (metallic pigment)

-

Resin binder system

-

Fillers

-

Solvents / thinners

-

Functional additives

Among these materials, aluminum powder is the core element responsible for metallic brilliance and reflective performance.

2. Core Functions of Aluminum Powder in Silver Paint

2.1 Creating Strong Metallic Appearance

High-quality aluminum powder features uniform flake structures and excellent reflectivity. When dispersed in coatings, these flakes align evenly on the coating surface, forming a smooth and bright metallic effect.

2.2 Enhancing Decorative Performance

Properly distributed aluminum flakes improve the depth, texture, and three-dimensional appearance of coatings, making silver paint more attractive and suitable for premium decorative applications.

2.3 Improving Film Density and Protection

The layered structure of aluminum powder forms a compact barrier within the coating film. This reduces porosity and enhances resistance against moisture, chemicals, and environmental exposure.

2.4 Improving Weather Resistance and Aging Performance

Aluminum powder reflects ultraviolet and infrared radiation, lowering surface temperature and slowing down aging processes. This significantly improves the outdoor durability of metallic coatings.

3. Influence of Aluminum Powder on Coating Adhesion and Stability

When properly formulated, aluminum powder contributes not only to appearance but also to mechanical strength and long-term stability.

3.1 Improving Adhesion to Substrates

Through optimized particle size control and surface treatment, aluminum powder achieves better compatibility with resin systems, resulting in stronger bonding to metal, plastic, and composite substrates.

3.2 Reducing Peeling and Cracking Risks

Uniform dispersion prevents internal stress concentration, helping minimize cracking, peeling, and delamination during long-term use.

3.3 Ensuring Long-Term Color Stability

Premium aluminum powder maintains stable brightness and color tone, preventing darkening, fading, and oxidation over time.

4. Scientific Formulation and Processing of Aluminum Powder

Proper formulation techniques are essential to fully utilize aluminum powder performance.

4.1 Optimizing Dosage Levels

The aluminum powder content should be adjusted according to metallic effect requirements. Excessive dosage may reduce adhesion, while insufficient dosage weakens metallic appearance.

4.2 Using Low-Shear Dispersion Methods

High-speed mixing may damage flake structures. Medium or low-speed dispersion is recommended to preserve particle integrity.

4.3 Controlling Solvent Ratios

Balanced solvent proportions help aluminum flakes align properly, improving surface smoothness and uniformity.

4.4 Applying Specialized Additives

Dispersants, anti-settling agents, and stabilizers enhance system stability and prevent sedimentation and separation.

5. Typical Application Areas of Aluminum Powder-Based Silver Paint

Due to its excellent performance, aluminum powder silver coatings are widely applied in:

-

Steel structure protection coatings

-

Industrial machinery painting

-

Automotive and auto parts coatings

-

Home appliance shells

-

Metal furniture finishing

These industries demand both aesthetic quality and long-term durability.

6. Value of High-Quality Aluminum Powder for Coating Manufacturers

Selecting premium aluminum powder brings multiple benefits to coating producers:

-

Improved product quality and market competitiveness

-

Reduced quality complaints and warranty risks

-

Higher customer satisfaction

-

More stable formulation systems

Reliable raw materials are essential for consistent coating performance.

7. Future Development Trends of Aluminum Powder in Metallic Coatings

With increasing emphasis on environmental protection and high-performance coatings, aluminum powder technology continues to evolve toward:

-

Water-based compatible aluminum pigments

-

Low-VOC coating systems

-

Enhanced corrosion resistance

-

Improved dispersion stability

These innovations will further expand the application scope of aluminum powder in modern coatings.

Conclusion

As a core functional pigment in silver paint, aluminum powder plays a vital role in providing metallic brilliance, improving coating adhesion, and enhancing weather resistance. Through scientific formulation and proper processing, aluminum powder can significantly increase the value and reliability of metallic coatings.

In the future, aluminum powder will remain a key material supporting the sustainable development of the global coatings industry.