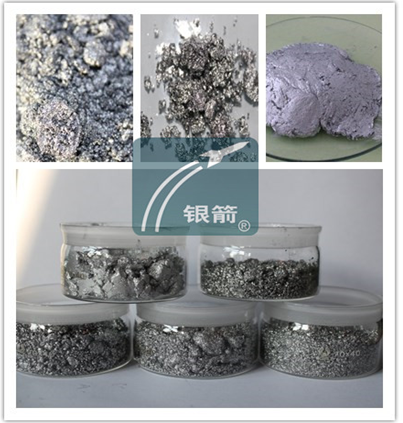

Storage and use of aluminum paste

2018 / 11 / 20

Aluminum paste contains a certain amount of acting mineral oil, additives, etc., in order to

ensure its good storage stability and dispersibility, so aluminium paste

requires good sealing. If open a bucket

of aluminum paste, you can't completely use it, you must seal it immediately.

Otherwise, if contact with air for a

long time, it will cause air-drying oxidation and cause poor dispersion. The

paint film will be granulated and blackened and coarse. Under normal circumstances,

aluminum paste with intact sealed package can be stored for more than one year.

The most important process of aluminum paste is dispersion. Generally, aluminium paste is pre-dispersed in a solvent. If a suitable wetting agent is added, it can be soaked for a period of time, then slowly stirred into a uniform slurry, and finally added to the pre-formed paint to obtain the most good process effect.

The solvents commonly used in pre-dispersion are generally: esters, ether alcohols, alcohols, aromatics, etc., and the esters have the best effect. It is also required that the solvent does not contain moisture, otherwise the pigment easily reacts with water, causing instability of the system. From this point of view, the aromatic solvent generally has a lower moisture content and seems to be better. The ratio of aluminum paste to pre-dispersed solvent is generally from 1:1 to 1:2.

In the process of dispersing aluminum paste, high shear force should be avoided to stir, which is easy to cause deformation of thin aluminum sheet, thus affecting the appearance effect, so it should be dispersed by low-speed slow stirring. The optimum dispersion speed and time should be determined experimentally.

Aluminum paste also has certain requirements on the paint. If the acid value of the paint is too high, it will affect the storage stability of the paint, resulting in blackening of the paint and coarsening.